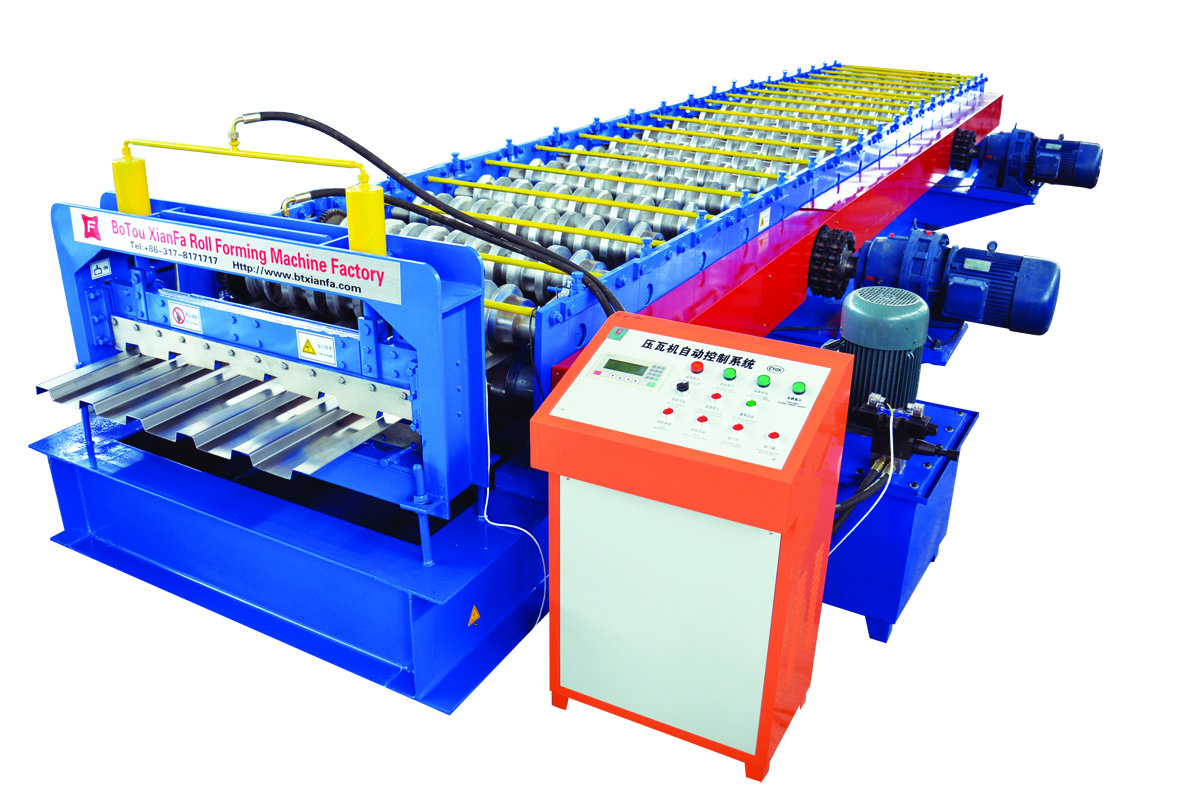

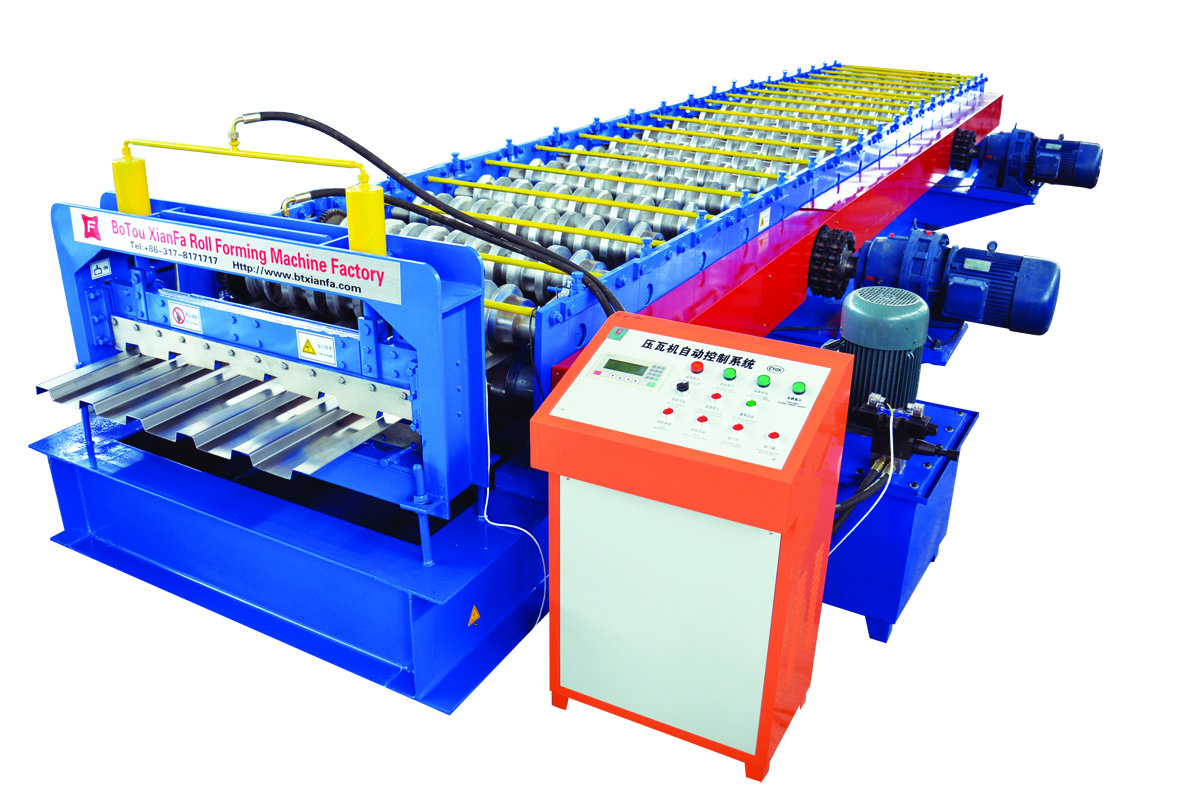

Cold Roll Forming Machine

The metal profile produced by Roll Forming Machine look beautiful, elegant and noble. They are widely used for garden, factory, hotel, exhibition center and villa, etc.

Cold Roll Forming Machine Components:

Roll forming machine consists of Uncoiler, Coil sheet guiding device, Main roll forming system, Post cutting device, Hydraulic station, PLC control system and Support table.

Optional with Hydraulic Decoiler, Auto Stacker, Safe Cover, Pre-Cutting, Film Covering Device, and so on.

Cold Roll Forming Machine Working Flow:

Decoiling→Feeding & Guiding→Flattening(If needed)→Pre- Punching/Cutting(If needed)→Roll Forming→Post Step pressing/Punching(If needed)→Post Cutting→Finished Products To Support Table

Parameter:

1.Suitable to process:Colored Steel plate, galvanized board

2.Width of the plate:1000/1200/1250mm

3.Roller stations:10-19rows

4.Rolling material: Forging Steel 45#

5.Rolling galvanization thickness:0.05 mm

6.Material of the cutting blade :Cr12

7.Hydraulic oil :40#

8.Dimensions: 9000mm*1700mm*1600mm

9.Motor:4+4kw

10.Thickness of the plate:0.3-0.6mm

11.Productivity:8-10m/min

12.Diameter of the roller:70mm

13.Weight:About 4.6 T

14.Voltage:380V 50Hz

15.Processing precision : within 1.00mm

16.Transportation:one complete machine need one 40feet container to hold

17.Payment term:30%deposit,and balance before delivery

18.Standard components: Chain 1 pcs, Hydraulic oil pipes: 2 pcs, electromagnetism valves 1 pcs. limit switch:2 pcs

19.This machine is composed of feeding table,forming machine, pressing device,cutting device, hydraulic system,computer control system,discharge table.

Optional devices have manual uncoiler,hydraulic uncoiler,auto stacker and so on.

Inquiry Basket ( 0 )

Inquiry Basket ( 0 )

Contact Now

Contact Now