Color Steel Sheet Wall Panel double Roll Forming Machine

double Metal Sheet Roll Forming Machine,Steel Tile Form Machine,Wall Panel Cold Roll Forming Machine

This type of sheet can be widely used in plant, house, storage and simple

steel roof and wall. It has advantage of pretty appearance, durable using and so on.

This is a single layer roll forming machine. Its working speed is 8-10m/min.

It's raw material can be color steel sheet, aluminium sheet, galvanized sheet. We can send you a manual decoiler for free.

We can customize roll forming machine according to your roof sheet or wall sheet profile drawing.

If you have the profile drawing of roofings and wall sheet, please send it to me.

Color Steel Sheet Wall Panel double roll forming machine

Quick Detail

1.Suitable to process: Color steel plate

2.Width of the plate: 1250mm

3.Rollers: Up layer:15 rows Down layer:17rows

4.Dimensions: 9.6*1.55*1.91m

5.Power: 4+4kw

6.Thickness of the plate:0.3-0.6mm

7.Diameter of the roller:Φ70mm

8.Weight: About 6.3T

9.Voltage: 380V 50Hz 3phases

10.Hydraulic: 40#

11.Processing precision: Within 1.00mm

12.Control system: PLC control

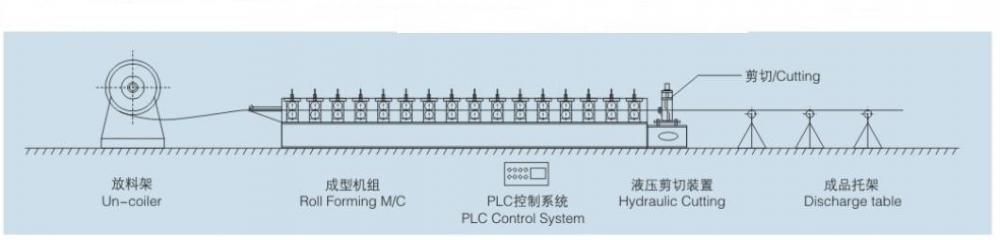

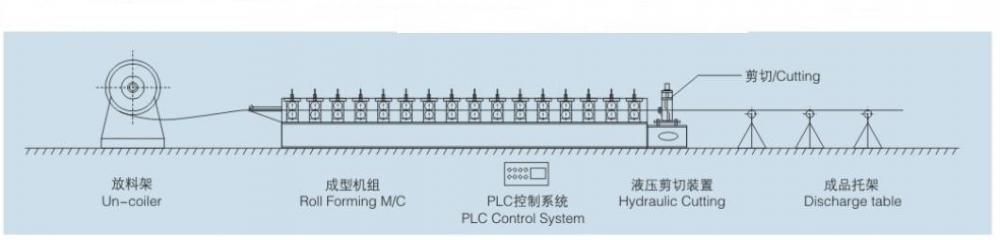

Industrial Process And Component Specification

Uncoiler

Usage:It is used to support the steel coil and uncoil it in a turnable way. The steel coil is uncoiled by hand.

Loading capacity:5000KG.Inner diameter: 500-508mm

Roller

Material of rollers:45# steel,roller surfaces polishing, hard plating ,

The polished surface and the heat treatment towards the molds also can keep the molding plate surface

smooth and not easy to be marked when it is being stamped.

Hydraulic and Control Systems

Hydraulic oil: 40#

hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job.

The target piece`s length is adjustable and digit of it can be adjusted.

Computed mode has two modes: automatic and manual one. The system is easy to operate and use

PLC: EURA(Can customize as customer require)

Shearing Mechanism

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products

Material of blades: Cr12,quenching treatment

Auto Stacker

Start reducer quickly after finish cutting products, deliver products to hold arms by deliver rollers .

then pneumatic control stack on the store table which is movable. Pneumatic pump (power sources) is self supply.

Packaging & Shipping

Company Certification

looking for ideal Roll Forming Machine Manufacturer and supplier

We have a wide selection at great prices to help you get creative.

All the Roll Forming Machine are quality guaranteed.

If you have any question, please feel free to contact us.

Product Categories : Roll Forming Machine Series > Double Layer Roll Forming Machine

Inquiry Basket ( 0 )

Inquiry Basket ( 0 )

Contact Now

Contact Now

Contact Now

Contact Now