Inquiry Basket ( 0 )

Inquiry Basket ( 0 )

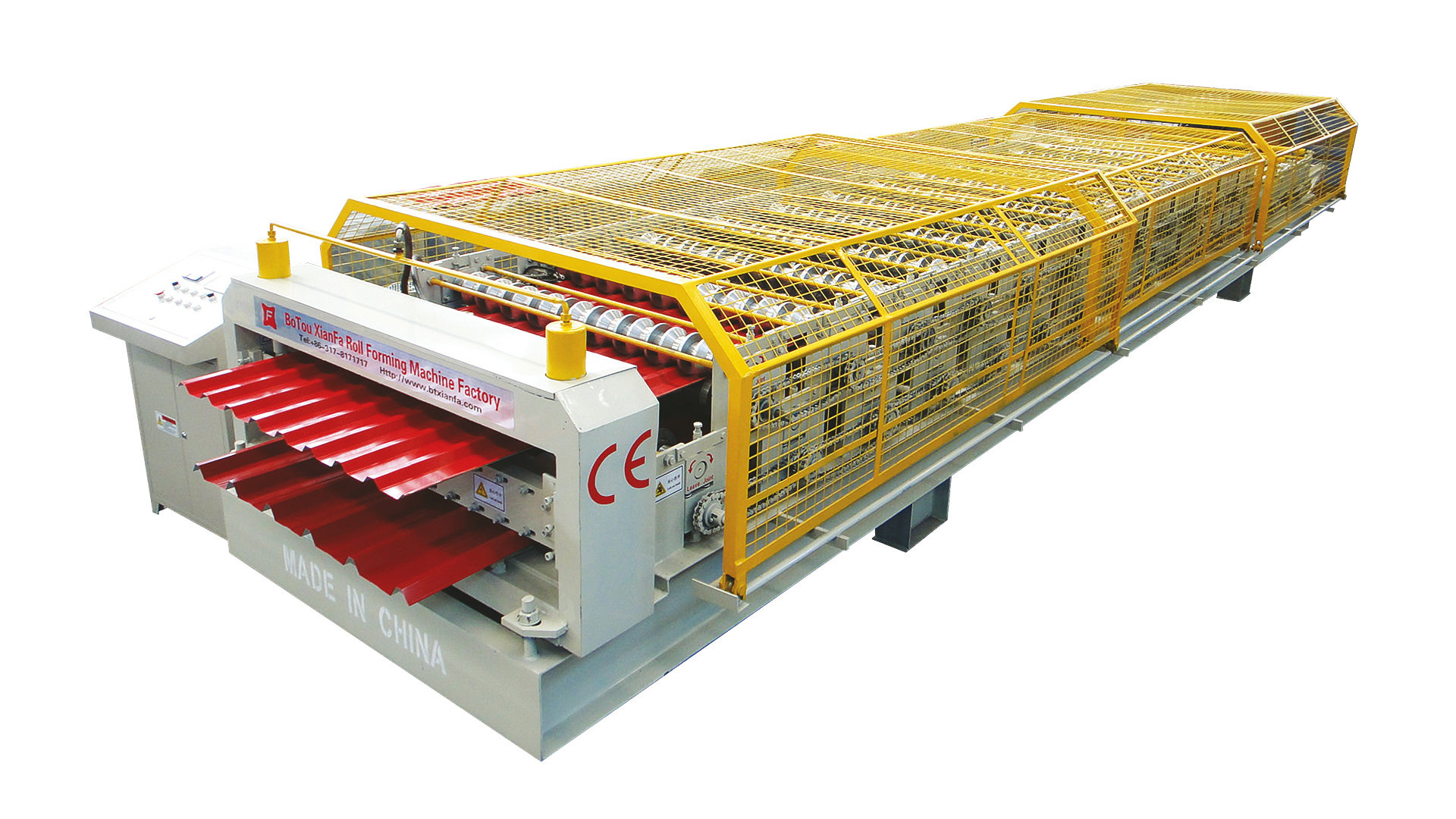

Botou Xianfa Roll Forming Machine Factory

- [Hebei,China]

- Business Type:Manufacturer

- Main Markets: Africa , Americas , Asia , Caribbean , East Europe , Europe , Middle East , North Europe , Oceania , Other Markets , West Europe , Worldwide

- Exporter:91% - 100%

- Certs:CE, ISO9001

- Description:double layer roll forming machine,roof sheet forming machine,double layer sheet roll forming machine,iron sheet making machine

Click for details

Click for details

Contact Now

Contact Now